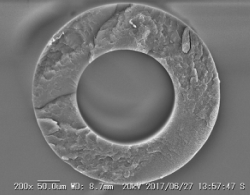

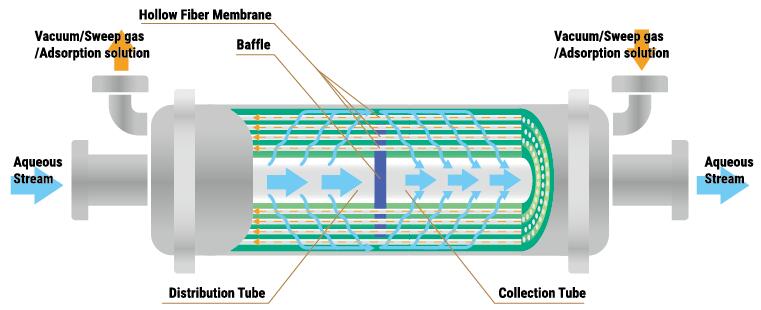

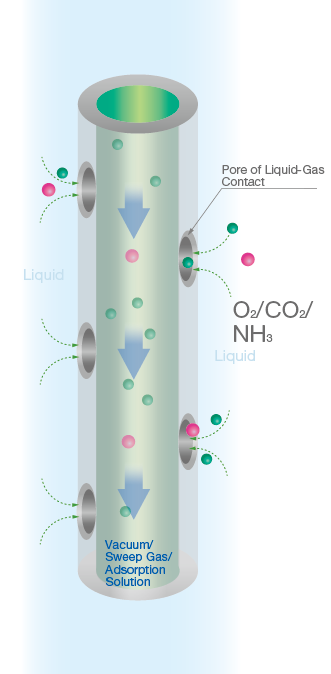

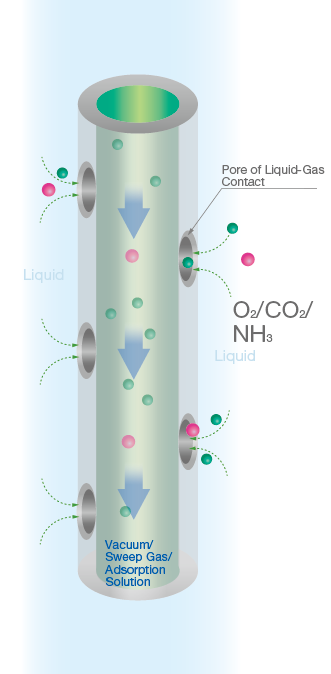

In medical industry, the water used in the pipeline already has high enough purity, but the dissolved gases (such as O₂, N₂, CO₂, etc.) and visible bubbles in the water will be generated in various environments, or react with reagents, causing inaccurate sampling. These gases are bound to cause great interference to the micro quantitative medical test, especially the clinical test results. The function of degassing membrane contactor is to remove the gas attached to the solution and eliminate the interference to the detection process and results. In a typical operation, the liquid flows outside the membrane, and the membrane is vacuumized or purged with gas. There are many micropores on the surface of hydrophobic membrane, which allow gas to pass through but prevent liquid from penetrating. The gas continuously moves to the inner part of the hollow membrane through the micropores and is taken away, so as to achieve bubble removal.

|

|