Medical Devices |

Infusion Devices | IV Catheter, Arterial Syringe Devices |

Drug Delivery Components |

Infusion Therapy Vents (venting membranes for IV spike, IV Filter, Prime Stop Cap) |

Injection Control | Reusable Sterilization Containers, use PTFE reusable filter, withstand repeated sterilization cycles of high temperature and pressure, remain stable bacteria resistance BFE99.99%. |

Lyophilization Tray, Bone/Tissue Protection Package, use PTFE lyophilization vent filter, ensure low temperature stability, as sterile barrier with BFE99.99%. |

Drainage | Ostomy System, Urinary Drainage Bag |

Sensor Application☆ |

Sensor Protective Filter | Sensor protection skived PTFE membrane is designed to protect the sensor from dust, water and other pollution sources, and balance the internal and external pressures to improve the sensor life term. |

Air Monitoring Sensor | For environmental gas analysis applications, the specially treated PTFE filter can specifically adsorb single or multiple gases that may interfere the sensor reading, including H2S, SO2, HMDS, organic substances, alcohol, etc. |

Electrochemical Sensor | PTFE catalyst carrier filter can collect current, and is not easy to shrink or deform due to the curing of the catalyst. It has the characteristics of high pressure resistance. |

In-Vitro Diagnostics |

Sample Analysis | Regent carrier, Sample Filtration, Wick, Vent |

Lab Analytical Science |

Chromatography | Solid Phase Extraction (SPE) frits, Automated pipetting system |

Specially treated PTFE pipette filter, used to capture and bind specific target substances |

Protein concentration, purification and filtration, retain organic solvents |

Purification and Extraction | DNA/RNA extraction and purification, Reagent carrier |

Bio-processing Media | Disposable biological processing media and filters |

Automotive and Aerospace |

Lighting | Vent for automotive lighting shell, balance the pressure, prevent moisture entering, and is tough and durable. |

Battery | Battery vent, safety isolator, easy for assemble |

Powertrain | Engine system vent, waterproof and oil-proof |

Fluid Reservoir | Fluid reservoir vent |

Electronic Products |

Acoustics | Mobile electronic components, water-proof and acoustic vent |

Flow modulator, balance the airflow pressure in the speaker room |

Mobile Electronics housing | Mobile electronic products vent, providing IP protection above IP6 |

Outdoor electronics housing vent |

Telecommunication | Low dielectric media in antennas and cables |

UVC Reflective Media

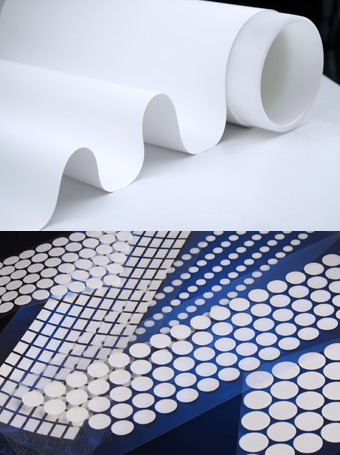

Cobetter microporous PTFE sheets provide reliable resistance to degradation, high reflectivity, and diffuse (Lambertian) reflectance |

UVC Disinfection | Air conditioning system disinfection, using Ultraviolet light reflective membrane |

Air purifier, using UV light reflective membrane |

Closed disinfection system, using Disinfection Ultraviolet light reflective PTFE membrane |

UVC lighting system, using Disinfection UV light PTFE membrane |

Robot and mobile disinfection system, using Ultraviolet light reflective sheet |

Portable handheld UV system, using Ultraviolet light reflective sheet |

Household water disinfection system, using UV light reflective sheet |

Building water disinfection system, using UV light reflective sheet |

Personal water disinfection system, using UV light reflective sheet |

UV Applications | Phototherapy, using Ultraviolet light reflective PTFE membrane |

UV curing, using Ultraviolet light reflective PTFE membrane |

| Integrating spheres, using UV light reflective PTFE |

| Architectural lighting, using UV light reflective PTFE |

| LED application, using UV light reflective PTFE |

Multiple optical test applications, in photometry equipments, using UV light reflective PTFE |

Industrial Applications |

Fuel system | Marine fuel vent, Oleophobic PTFE membrane, reduce hydrocarbon emissions |

Fuel filtration and vent for small engine systems |

Industrial Packing | Covering or packaging material for industrial and household containers |

Petroleum and Gas | Transmission ventilation system vent |