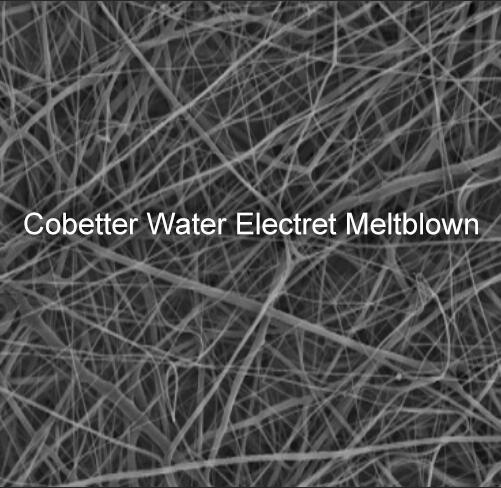

Cobetter water electret meltblown, compared with traditional electric-electret meltblown, has higher filtration efficiency and lower resistance, which can meet the ASTM American mask standard《ASTMF2100-2019》LEVELⅡ and LEVELⅢ.

Compliance with American mask Standard《ASTMF2100-2019》LEVELⅡ & LEVELⅢ levels

The core of PPE protective facial mask is meltblown. The traditional corona thermal electret electrostatic meltblown material is made of polypropylene, adding corona when it is heated, thus formed not a permanent electrostatic electret, with little electricity charged and uneven distribution. When producing into masks, it needs stacking more polypropylene filaments to reach the qualified filtration efficiency, thus the breathing resistance will be high. Therefore, for the American standard LEVELⅡ\LEVELⅢ masks that require extremely high filtration efficiency and low respiratory resistance, it is difficult for ordinary meltblown to meet both requirements at the same time. If the filtration efficiency is high, the corresponding resistance will exceed standard.

| Cobetter water electret meltblown, passing through a water electret equipment, firstly undergoes a cold water cooling, the pure water passes through a certain angle, pressure, and flow rate to spray the meltblown. The friction between the water and the meltblown cloth generates static electricity, which is transported through conductive material in the electret masterbatch and enters into tourmaline or zircon to achieve static retention. The advantage of water electret lies in its electrification process, which is carried out in a high humidity environment. The static electricity on the surface of the meltblown cloth is washed away by the water, leaving only the static electricity inside the meltblown.

|

The second process of water electret is a process of drying and electricity locking for meltblown. The drying process uses the flow of hot air, the surface temperature is increased and the surface air flow is increased to dry. This process is actually a working principle of a static elimination equipment. All of the electricity staying outside of the electret masterbatch, will be taken away. In this second process, a part of the electricity on the surface of the meltblown cloth is eliminated, that is, virtual electricity. Therefore, after the above two processes, the electret on the polypropylene can be guaranteed to be permanent.

Compared with the traditional corona thermal electret electrostatic meltblown material, water electret meltblown is more saturated with static electricity, and its electrostatic retention is more than three times that of the electric electret, so the corresponding filtration efficiency is higher. Because the electric field is high, there are few materials to be stacked, thus the amount of polypropylene stacked is only half of the electric electret. The material required is thinner, and the breathing resistance is correspondingly lower.

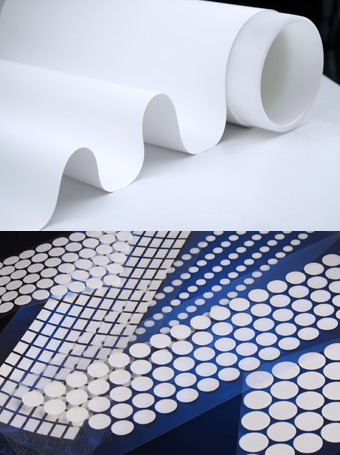

Cobetter meltblown adopts Japanese original production line, guarantees that all production and packaging are completed in a 100,000-class clean room to ensure high cleanliness.

Cobetter experiments have verified that, target for American standard《ASTMF2100-2019》 LEVEL Ⅱ, LEVEL Ⅲ masks, Cobetter water electret meltblown can achieve the requirement of 98% filtration efficiency under the premise that the resistance is not exceeded.

Features and Advantages

Saturated amount of static electricity, High particle filtration efficiency

Few Polypropylene stacking volume, Low resistance

LEVELⅡ & LEVELⅢ Standard

| BFE | Differential Pressure (pa) | PFE (%) |

Level II | 98 % | 50 | 98 |

Level III | 98 % | 60 | 98 |

Remarks:《ASTMF2100-2019》requires, the bacteria filtration efficiency of LEVELⅡ and LEVELⅢ masks achieve 98% or higher, differential pressures are less than 50pa and 60pa respectively, and filtration efficiency for 0.1μm latex particles is higher than 98%.

Links:

Cobetter water electret meltblown-compliance with FFP2 & FFP3 standards

Cobetter PTFE mask membrane-meet EU mask standards《EN14683:2019+AC》TYPE ⅡR level

For technical data sheet or application inquiry, you are more than welcome to contact our sales representative by sales@cobetterfilter.com or leave a message