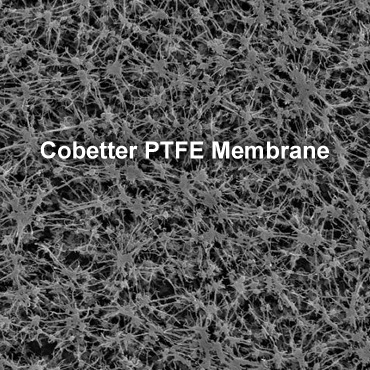

Cobetter Nano PTFE microporous membrane for protective facial masks, the bacteria filtration efficiency can reach more than 99%. It has excellent air permeability, low breathing resistance and long service life, meets the requirements of European mask standard 《EN14683:2019+AC》 TYPE ⅡR. It is the new direction for the development of facial mask materials.

Four Features of Nano PTFE Membrane

Cobetter Nano PTFE mask membrane is one of its innovative material. The facial mask made of this membrane has following four features:

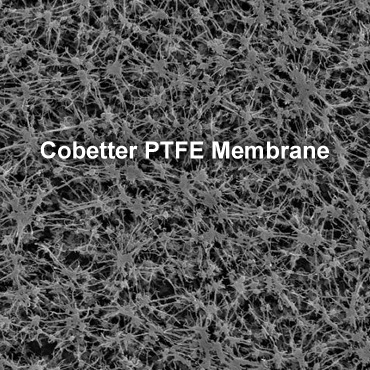

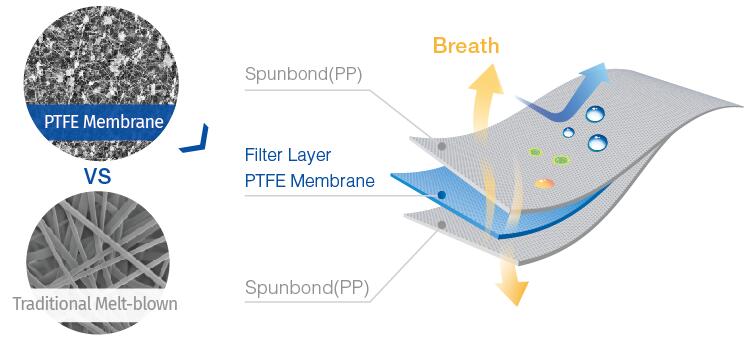

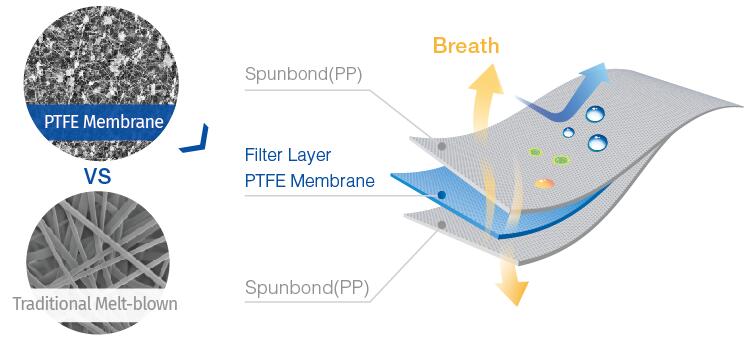

| Higher Filtration Efficiency (PFE & BFE) The pore size of PTFE membrane is smaller than the fiber diameter of traditional materials (the fiber diameter of the non-woven material used in traditional masks is more than 2000 nanometers), which can more effectively block PM2.5 (particles whose aerodynamic equivalent diameter less than or equal to 2500 nanometers) in the air, and effectively reduce the concentration of bacteria and viruses in the inhaled air, and the retention capacity of bacteria reaches more than 99%.

Naturally Fydrophobic Property

The natural hydrophobic property of PTFE membrane, make it effectively isolate blood splashes, and effectively isolate splashes of body fluids carrying the COVID-19 virus, such as droplets and sneezing. According to CDC's guidelines, the spread of the virus is mainly through droplets, sneeze, aerosols and other channels. PTFE membrane can block these liquids in social situations through the hydrophobic properties of its surface and establish an effective isolation barrier.

|

Breathe Freely

Breathe more easily and freely when wearing this kind of masks. The extremely high porosity and ultra-thin membrane thickness of <5μm make it results in better air permeability, low breathing resistance, and comfortable wearing.

Create Longer Validity for Masks

Benefits from its natural hydrophobic characteristics and microporous structure, Cobetter PTFE membrane block particles through pore size interception. It uses physical principles to mechanically intercept air pollutants, and will not reduce the interception rate due to moisture in the breath. The protection effect is more stable and lasting compared with the electrostatic adsorption principal of ordinary meltblown. Due to the large fiber diameter of the non-woven fabric material used in traditional masks, it needs to rely on static electricity to absorb particles. Static electricity is easily affected by temperature and humidity in the environment, and the static content will gradually decrease, results in protective efficiency reduced. Users who purchase PTFE filter membranes as the main filter layer of masks will benefit from it. Research has shown that traditional electrostatic electret meltblown materials have reduced PFE by 3% to 5% after storage for 3 to 5 months. However PTFE membranes do not have efficiency degradation during the 5-year validity period.

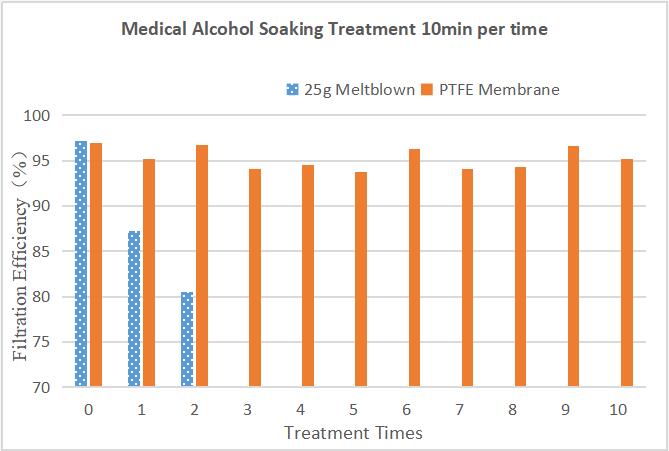

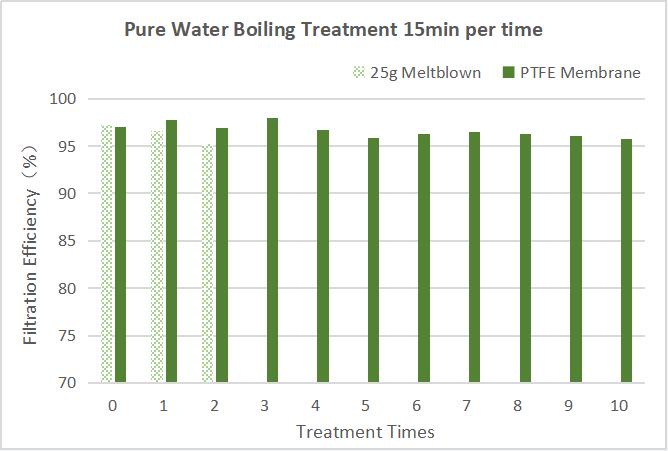

Repeated Use Testing

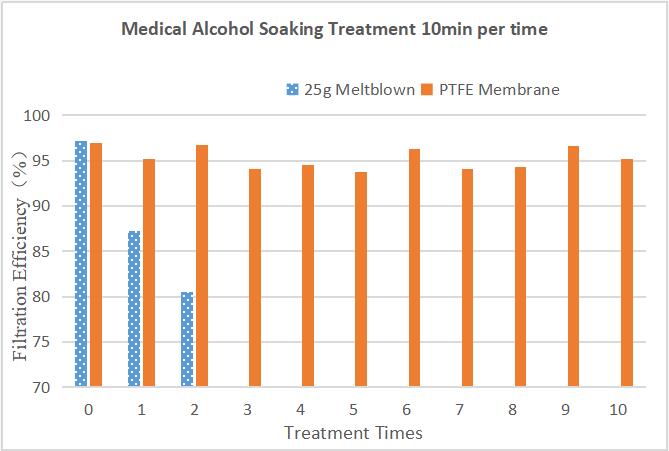

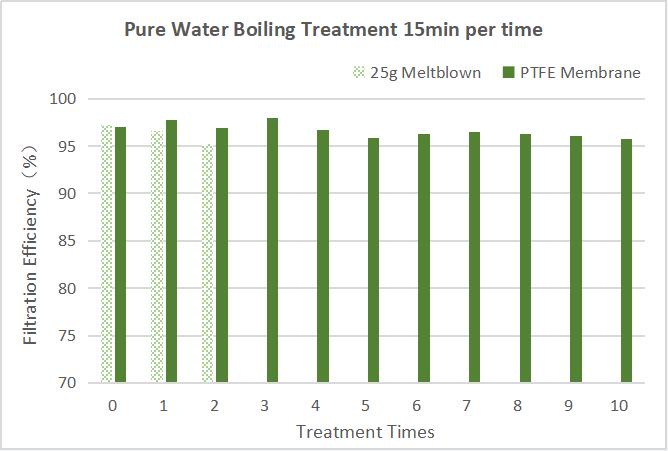

The data shows that PTFE membrane can withstand repeated alcohol disinfection or boiling water disinfection.

Repeated test results of ordinary meltblown fabric and Cobetter PTFE membrane:

Remarks: Experiments shows, the filtration efficiency of meltblown material is significantly reduced after the medical alcohol soaking treatment and the pure water boiling treatment, while the overall efficiency of the Cobetter PTFE membrane can be maintained at around 95% in the 10 times treatment experiments.

Production Base From production to packaging, Cobetter nano PTFE membrane is completed in a 100,000-class clean room to ensure high cleanliness. The material can be used for medical-grade masks. |

PTFE membrane production workshop |

Features and Advantages

BFE>99%

Physical retention, high particle filtration efficiency (PFE)

Low breathing resistance, smoother breathing

Physical interception, longer protection

Tolerate E-beam irradiation sterilization

《EN14683:2019+AC》TYPE ⅡR Standard:

| BFE (%) | Differential Pressure (Pa/cm²) |

TYPE ⅡR | ≥ 98 | < 49 |

《EN14683:2019+AC》requires the TYPE ⅡR mask has bacterial filtration efficiency ≥98% and Differential Pressure (respiratory resistance) <49Pa.

PTFE Membrane Testing Results:

| BFE (%) | Differential Pressure (Pa/cm²) |

PTFE Membrane | ≥ 99 | < 35 |

With testing and verification, the facial masks made of Cobetter single-layer PTFE membrane can meet the requirements of EU mask standards《EN14683:2019+AC》TYPE ⅡR level.

Links:

Cobetter water electret meltblown-compliance LEVEL2 / LEVEL3 standard

Cobetter water electret meltblown-compliance FFP2 & FFP3 standards

EVS_EN_14683_2019_en.pdf

EVS_EN_14683_2019_en.pdf

For technical data sheet or application inquiry, you are more than welcome to contact our sales representative by sales@cobetterfilter.com or leave a message