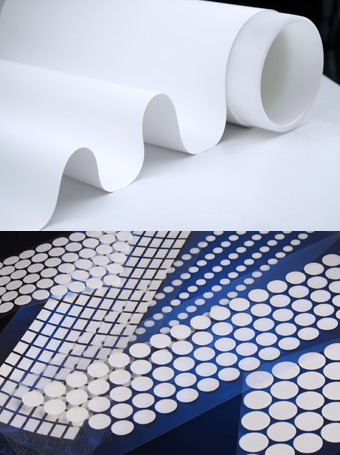

PTFE Membrane

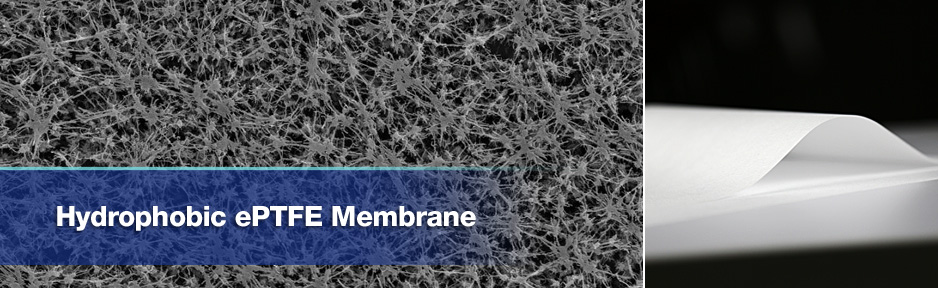

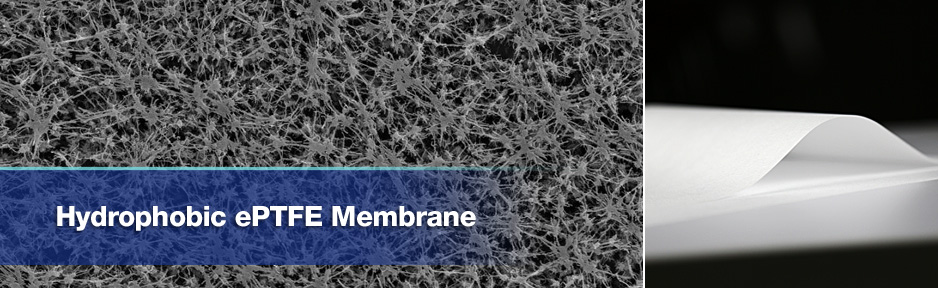

Polytetrafluoroethylene (PTFE) membranes are naturally hydrophobic, resistant to corrosion and organic solvents, and it is widely used in biofermentation, medical and food & beverge industries.

Cobetter's PTFE membranes are widely used in air filtration of major pharmaceutical companies and organic solvent filtration because of their high throughput, low differential pressure and low leachable.

Cobetter's gas sterilization cartridges use temperature-resistant, thickened PP center rods instead of traditional stainless steel center rods.

Due to Cobetter's technical innovation, it has also developed a hydrophilic PTFE that can be used in liquid filtration. Cobetter filter cartridge is particularly suitable for filtration of organic solvents and disinfectants that are soluble in water. What's more, Cobetter can make PFA perfluorinated cartridges, which are highly resistant to temperature, pressure and corrosion.

· Meets 107cfu/cm² according to ASTM F838 test method. Brevundimonas diminuta (ATCC*19146) Retention Test.

· Each cartridge is integrity tested before delivery to ensure sterilization effect

· "Non-fiber releasing" as defined by FDA 21 CFR 210.3(b)(6) Filter standards

· In-line steam sterilizable at 145°C for 30 min, 150 cycles total

· Autoclavable at 130°C for 30 min, cumulative 400 cycles

· Very clean membrane, very low extractables / leachables

· Very good resistance to corrosion, oxidation and organic solvents

· Chemically compatible, pH 1-14, temperature resistant to 180°C*

· Hydrophilic PTFE is particularly suitable for filtration of organic solvents and disinfectants that are water-miscible.

Ramoval Ratings (μm)

0.02 / 0.03 / 0.05 / 0.1 / 0.2 / 0.45 / 0.8 / 1.0 / 2.0 / 5.0 / 10.0 ...