Cobetter TefloGas® Filter Cartridges constructed of hydrophobic PTFE membranes and specially designed for the removal of microorganisms and particles from air and gases. Due to their inherently hydrophobic nature, these filters offer the highest level of sterility even with high volume gas streams, extreme humidity, and stringent in-line stream sterilizations.

Features and Benefits

· Inherently hydrophobic

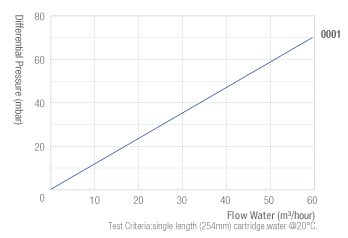

· High flow rates with low pressure drops

· Steam sterilization up to 150 cycles @ 121°C

· Integrity Tested by all methods including Water Intrusion Test

· Absolute-rated filter