Specification selection is from three aspects:

Step 1:Confirm membrane material.

Solution conposition, temperature, viscosity, surface tension, etc.

Degassing of pure water or aqueous solutions with low viscosity and high surface tension, PP fiber membrane can be selected. Or PMP fiber membrane can be selected.

Step 2:Refer to the flow requirements.

The larger the flow, the larger the size of the degassing membrane contactor.

Cobetter has developed a variety of different sizes of degassing membranes for medical industry, which greatly broadens the application scenarios.

Step 3: Confirm if connector matches.

Confirm the specification of vacuum port and liquid port.

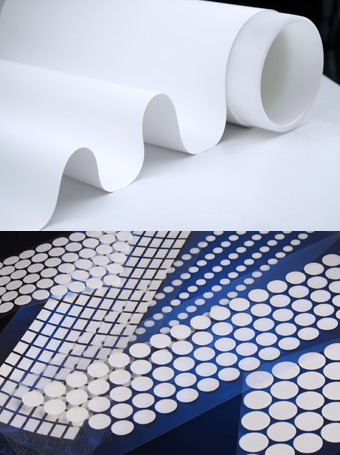

Membrane Material

| Material | Liquid Surface Tension Tolerance | Applicable Liquid Viscosity | FlowWay | Character |

PP

(Polypropylene) | Pure Water | ≤ 50cp | Liquid flows

over lumenside | Large flow volume |

PMP

(Polymethylpentene) | PM | ≥ 35 Dyne/cm | ≤ 50cp | Liquid flows

over shellside | Good Hydrophobicity; Longer service life |

| SP | ≥ 28 Dyne/cm | ≤ 10cp | Liquid flows

over shellside |

PTFE

(Polytetrafluoroethylene) | ≥ 20 Dyne/cm | ≤ 10cp | Liquid flows

over lumenside | Super hydrophobicity;

Tolerate to most

organic solvent |

Cobetter Degassing Membrane Contactor Specification List.pdf

Cobetter Degassing Membrane Contactor Specification List.pdf

For technical data sheet or application inquiry, you are more than welcome to contact our sales representative by sales@cobetterfilter.com or leave a message