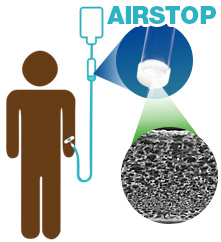

Cobetter’s Airstop membrane could blocks automatically the air passing when the infusion drip chamber runs empty. The surface tension of liquid within the porous structure of wet membrane automatically stops the flux, and form a fluid protection surface to protect the downstream infusion line from air entrance.Thense, the fluids will stay maintained in the infusion line under the drip chamber. It could prevent bubbles from entering the human’s blood vessel.The Airstop function could solidly last above 30mins while the patients are walking or moving around. Even with extremetly low surface tension drugs(i.e.Paclitaxel,Fat Emulsion Injection), it could still effectively maintain it’s airstop function.

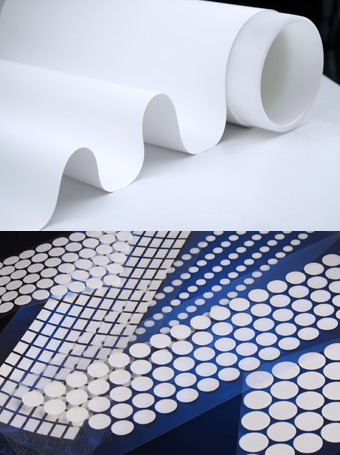

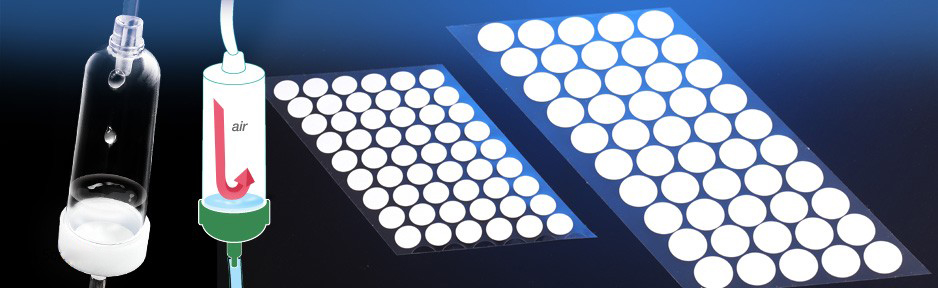

An airstop filter membrane is a highly hydrophilic porous disc membrane welded on the bottom of a drip chamber, the instant wetting ability active the membrane as an infusion flux filter once it contacts fluids. And the 5μm -15μm pore size range prevents air bubbles/particles/crystals from being injected into patients.The membrane combine the airstop function with the filtration function together perfectly. |