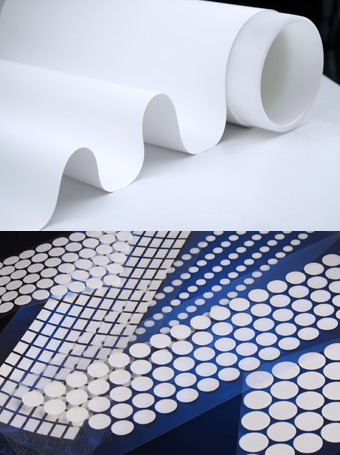

Non-dewetting modified membrane improves surface energy

Cobetter Chemrapid Filter Series are composed of a surface-modified PTFE membrane that is bonded with PFA which results in ultra low metal extractables. It solves the problem of defect fluidity when if filters foam. Chemrapid Filter Series improve flow performance, cleanliness and contamination control at low wafer defect levels for highly corrosive acids and bases. The modified PTFE membrane enables semiconductor makers to meet their critical chemical filtration requirements.

Superior filtration efficiency and high flow rate

They are suitable for filtration of H2SO4, H3PO4, HNO3, HCl, NH4OH, H2O2, TMAH and deionized water at room temperature and SC1, SC2, SPM, metal etching and other applications at high temp ratures. Excellent chemical compatibility and ultra-low metal extractables ensure superior filtration efficiency and extended service life. The non-dewetting PTFE membrane

increases the surface energy providing high flow rates and superior filtration efficiency. Ultra-pure cleanliness reduces equipment set up time. Its one-piece structural design makes it easy to install and replace. Available in T, L and In-line configurations which simplify system design.

Application

Feature

Excellent chemical compatibility

All fluorine construction makes it suitable for the filtration of highly corrosive high temperature chemicals.

Suitable for critical condition

100% integrity tested

High flow rates, low pressure drop, long service life

Low extractables

Provided prewet option, reducing equipment pre-operation time.